WETTING AGENT FireEx

TKW FireEx 3000 C

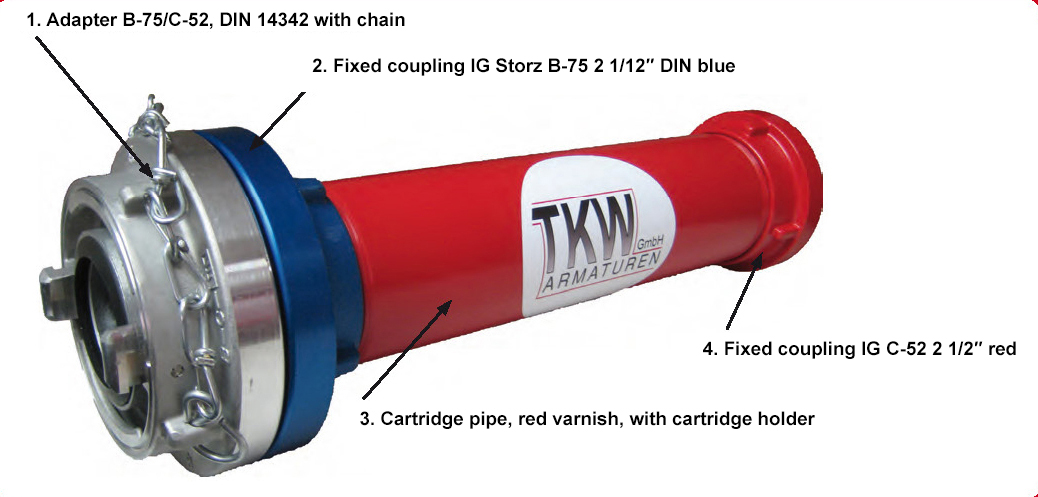

The wetting agent tank TKW Fire-Ex 3000 C is designed for firefighting wetting agent production and is especially tailored to the needs of the fire brigade. It convinces with its high performance flow rate of more than 500 l/min, a producible volume of more than 3000 l wet water as well as an unparalleled connectivity and compatibility. It is fitted in the Storz C hose line or in front of a distributor C/DCD and contains a cartridge with a concentrated wetting agent mixture, which is flushed with water and whose active ingredients are slowly released into the extinguishing water. All fittings of multi-purpose branch pipes DM, CM and BM can be used as well as hollow jet pipes or mist jet pipes with a flow rate of up to 500 l/min.

| Number | Description | Product no. |

|---|---|---|

| 1 | Adapter B-75/C-52, DIN 14342 with chain | 170091 + 910182 |

| 2 | Fixed coupling IG Storz B-75 2 1/12″ DIN blue | 130355 |

| 3 | Cartridge pipe, red varnish, with cartridge holder | 952215 + 290100 |

| 4 | Fixed coupling IG C-52 2 1/2″ red | 130225 |

| 5 | Box of cartridges 8 x 600g | 203009 |

TKW FireEx 3500 B

The wetting agent tank TKW Fire-Ex 3500 B is designed to produce wetting agent for firefighting and is a particularly powerful fitting. Due to its even larger DN80 diameter, the wetting agent tank TKW Fire-Ex 3500 enables operation both in front of and in type B hose lines as well as during cannon or monitor deployment. With a very low pressure drop of less than one bar at 1,000 l/min, the wetting agent tank does not limit the flow rate but rather enables very high flow rates and long distances. Like the Fire-Ex 3000 C, the Fire-Ex 3500 B is fitted in the hose line and contains a cartridge made of a concentrated wetting agent mixture which is flushed with water and whose active ingredients are slowly released into the extinguishing water. All fittings of multi-purpose branch pipes DM, CM and BM can be used as well as hollow jet pipes with a flow rate of up to 500 l/min.

| Number | Description | Product no. |

|---|---|---|

| 1 | Fixed coupling IG B-3″ LM blue | 130361 |

| 2 | Clamp fitting rotating IG B-3″ | 190051 |

| 3 | Cartridge pipe, red varnish, with cartridge holder | 952215 + 290100 |

| 4 | Box of cartridges 8 x 600g | 203009 |

| Product | Max. flow rate | Max. wetting water | Max. pressure | Pipe diameter | Product no. |

|---|---|---|---|---|---|

| FireEx 3000 C | 500 l /min | 3000 l | PN 16 | DN 65 | 203022 |

| Fire-Ex 3500 B | 1.500 l/min | 3500 l | PN 16 | DN 80 | 203023 |

TKW mixing valve FireEx

The gold standard in wet water production! Safe wetting agent production in one step, safe and easy to use, continuous water supply even during reloading, very easy and self-explanatory to operate without the possibility of operating errors, and with a flow rate of 0l/min up to 950 l/min.

The fitting with Storz C-52 (Fire-Ex 3000 C) or B-75 (Fire-Ex 3500 B) on both sides can be permanently installed in the vehicle or can get set up at the deployment site. The solid and durable frame ensures safe footing and the design of the fitting makes it easy and comfortable to refill in any position! The special feature of the mixing valve compared to the wetting agent tank is the unique ability to dispense both pure water and wetting agent. The machine operator can change the operating mode from « wetting water » to « water » at lightning speed with a lever, e.g. to reload a new wetting agent cartridge.

| Number | Description | Product no. |

|---|---|---|

| 1 | Fixed coupling AG C-52 | 140201 |

| 2 | 3-way ball valve | aA |

| 3 | Cartridge pipe with cartridge holder | aA |

| 4 | Drainage valve with elbow | aA |

| 5 | Fixed coupling AG C-52 | 140201 |

| Product | Max. flow rate | Max. wetting water | Max. pressure | Pipe diameter | Product no. |

|---|---|---|---|---|---|

| FireEx 3000 C | 500 l /min | 3000 l | PN 16 | DN 65 | 203022 |

| Fire-Ex 3500 B | 1.500 l/min | 3500 l | PN 16 | DN 80 | 203023 |